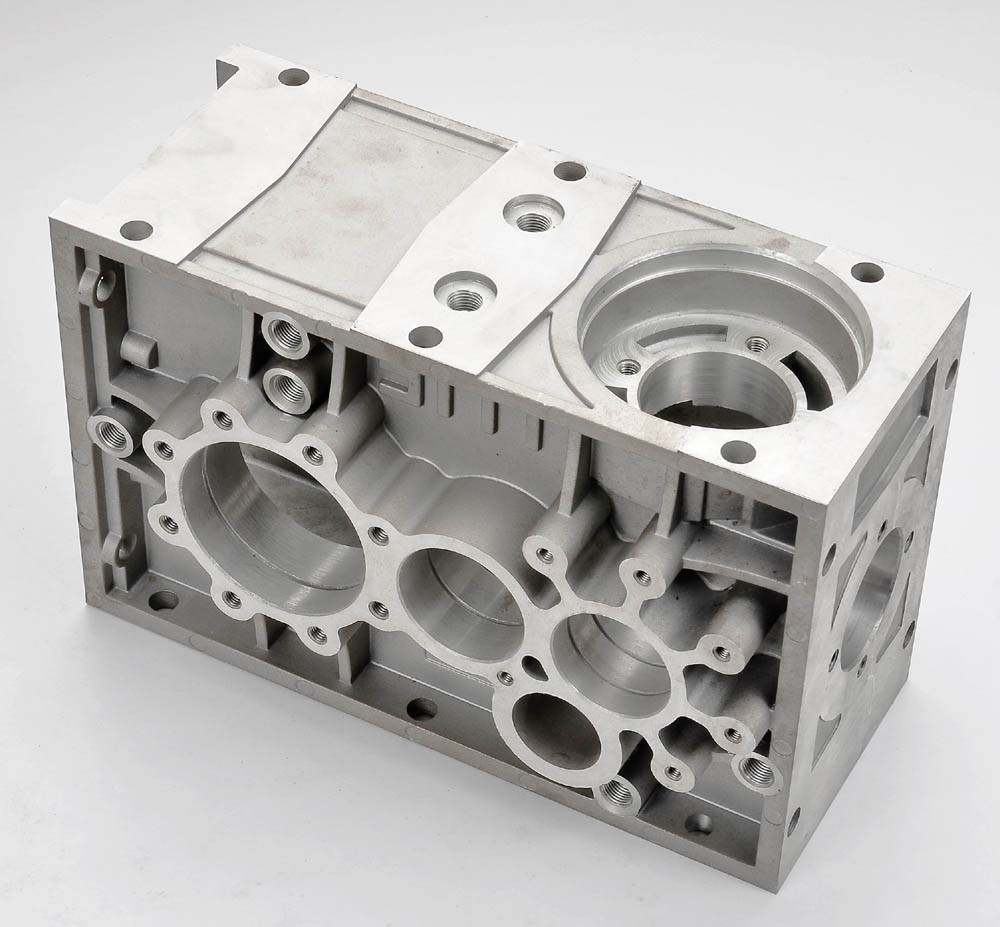

OEM High quality zamak connecting part

| Payment Type: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paybal |

|---|---|

| Min. Order: | 200 Piece/Pieces |

| Delivery Time: | 35 Days |

| Packaging: | zamak connecting part : 15-20 KGS IN ONE CARTON .THEN IN ONE PALLET |

|---|---|

| Brand: | HOTENG |

| Place of Origin: | Zhejiang, China (Mainland) |

| Supply Ability: | 200000 Piece/Pieces per Month |

Basic Info

Model No.: zamak connecting part

Product Description

| Product | zamak connecting part |

| Machine | die casting machine 120 ton- 1200 ton

Hot chamber Die casting machinies: 58T/88T/168T

CNC centers, Electrinc pluse, Wire EDM, milling, drilling, grinding

|

| Process | Drawing & Samples → Mould making → Die casting → Deburring→ Drilling and threading → CNC Machining → Polishing → Surface treatment → Assesmbly → Quality inspection → Packing → Shipping |

| SurfaceTreatment | Polishing, Sandblasting, Painting, Powder coating ,Galvanizing, Chrome plating |

| Application

| Led light housing & led heatsink Auto & motocyle & bicycle parts Furniture accessories Power tool housing Pump housing Furniture accessories Mechanical parts |

| Drawing file | IGS . STEP . SLD . X_T . DXF .DWG . SAT . STL. |

| ISO Certificate | ISO9001-2012 |

| Our advantage | More than 10 years of experiences in die casting field |

Furniture accessories

Power tool housing

Pump housing

Furniture accessories

Mechanical parts

Welcome your drawing & Samples .The drawing are available IGS , STEP , SLD , X_T . DXF .DWG. SAT. STL . Die Casting Parts for Lights & lamps

Die casting parts for automobile and motorcycle accessories

Die casting parts for automobile and motorcycle accessories

Die casting parts for Furniture hardware fittings

Die casting parts for Furniture hardware fittings  Our Die casting moulds

Our Die casting moulds

Packaging & Shipping zamak connecting part Export carton, wooden case, pallet or according to your requst To deliver on time Our Services zamak connecting part

1. Working Hour: -------------- 7:00AM--10:00PM (Beijing Time); 0:00AM--3:00PM (European Time); 3:00PM--6:00AM (LA Time); 7:00PM--10:00AM (Toronto Time)

2. Working Days: -------------- 7days a week, 365 days a year.

3. Feedback Time: ------------ with in 12 hours

Quotation Time: ------------ with in 48 hours 4. Manufacture schedule: --- we report our production schedule to customers everyday by mail or photoes, it's just like the production is happened under your nose. 5. Speed delivery:------------- The shipping date never late than settled. ( expect for force majeure.)

6. Quality control:-------------- Both in-house QC and lab test provided. Test report along with delivery according to customer's request.

7. Ningbo Hoteng Machinery CO.,Ltd is a manufacturer who can provide you one stop solution for all metal products. We can provide you from designing to delivery. The manufacturer process could be like this:

1.mould making

2.casting ( die casting, Sand casting, gravity casting, low pressure casting)

3.machining

4.welding (optional)

5.surface treatment (optional)

6.QC and package,

7.delivery.

Material could be aluminium, brass, copper, iron, steel, magnesium, zinc, etc.

Or the process could be like this:

1.material purchasing( billet aluminium 6061, 7075, 2024, iron tube, steel bar, brass block and magnesium block, ect.), or the material can be done by forging or extrusion,

2.machining,

3.welding, (optional)

4.surface treatment, (optional)

5.QC and package,

6.delivery. Company Information More than 10 years of experiences in die casting field

With talented and experienced engineers, All staff here are aimed to provide top quality products and make our clients experience the most comfortable and convenient customer service. Our factory

Our die Enquipment

Our workshop

Our showroom

FAQ zamak connecting part

Q1: Are you a manufacturer or trading company?

A1: Hoteng is an OEM die casting and mould making factory

Q2: What kind of production service do you provide?

A2: Mould making, Die Casting, Sand Casting, Gravity Casting, Low Pressure Casting, Machining Parts.

Q3: What’s the mould life time?

A3: Aluminum Die Casting mould 50,000 - 100,000 shots. Zinc die casting mold 100,000 - 300,000 shots. Brass die casting mold 5,000 – 15,000 shots. Sand casting mould 50,000 – 70,000 shots.

Q4: What’s the mould making time?

A4: Usually, die casting mould 35 - 55days. Q5: What’s the lead time of production samples? A5: Usually 5 days after mould's done. Contact us if you need more details on Zamak Connecting Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Zinc Alloy Connecting Part、Connecting Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Zinc die casting

Premium Related Products